The gas-sensing ability of these composite films is demonstrated. The electrical and mechanical characteristics of free-standing composite films prepared by evaporative casting and vacuum filtration were assessed, including the effect of incorporating the plasticizer glycerin. The KC concentration and sonication time were optimised to facilitate the efficient dispersion of these CNTs. In this work, it is shown that kappa-carrageenan (KC) is a suitable dispersant for the stabilization of SWNTs and MWNTs in water. Of particular relevance to the research presented in this paper is its usage as a plasticizer to increase the flexibility of polymer films. For example, in the food industries it is added as a humectant, while it is also used to produce an essential ingredient (glyceryl nitrate) for explosives.

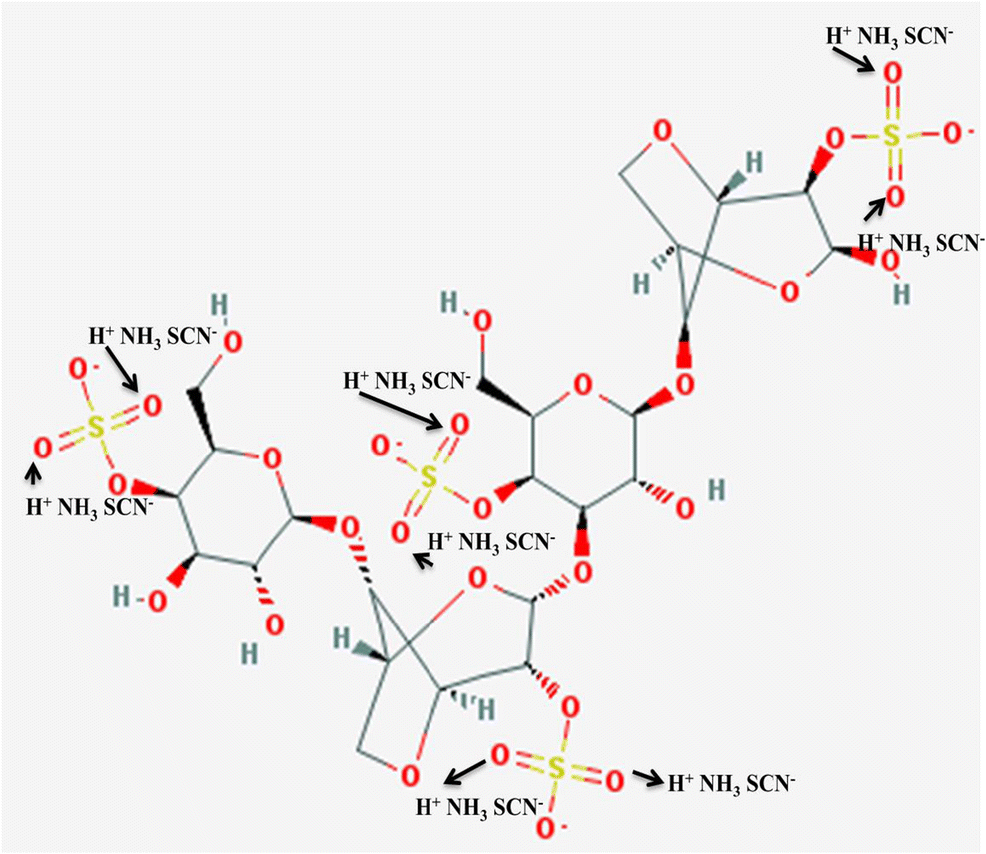

Glycerin (or glycerol, glycerine) is a polyol compound widely used in a diverse range of industries. Recent demonstrations of other applications include their use in drug delivery for the inhibition of viral infections. Carrageenans have been extensively employed in the food industry and are commonly referred to as E407 (European Union specification) as well as being approved by the US Food and Drug Administration as a direct food additive. There are three types of carrageenan depending on the number of charged sulfated groups per biopolymer repeat unit, i.e., kappa-carrageenan (one group), iota-carrageenan (two groups) and lambda-carrageenan (three groups). This biopolymer is an anionic polysaccharide whose structure contains galactose, 3,6-anhydrogalactose units, carboxy and hydroxy groups and ester sulfates. The carrageenans are well known for their gel-forming and thickening properties. Ĭarrageenans are a biopolymer family of water-soluble, linear, sulfonated galactans extracted from various sources of the Rhodophyta (marine red algae). The electrical properties combined with their flexible nature makes CNT networks ideal for a number of potential applications, such as solar cells, displays, touch screens, sensors, electronic paper, supercapacitors and batteries. Although the formation of buckypapers is straightforward, it has been shown that the electrical, mechanical and physical characteristics are dependent on various parameters, such as the type of CNTs (SWNT or MWNT), the filtration substrate (pore size hydrophilic or hydrophobic), the sonication time and the type of dispersant (surfactants or polymers). These films can be defined as an entangled network of CNTs, which are held together by van der Waals interactions at the CNT–CNT junctions and are arranged in a two-dimensional structure. Vacuum filtration of dispersions usually results in films, which are generally referred to as buckypapers. Increasing the nanotube concentration usually leads to an increase in the electrical conductivity and to mechanical reinforcement. It has been established that the mechanical and electrical characteristics of these CNT networks are contingent on the CNT/dispersant ratio. Formation of films by evaporation is well-known and involves the controlled evaporation of the solvent from a CNT dispersion. Other commonly employed wet-processing methods used to process biopolymer–CNT dispersions into materials include (but are not limited to) evaporative casting, vacuum filtration and fibre spinning.

For example, gellan gum-CNT dispersions have been wet-processed by inkjet printing into optically transparent films, which displayed sensitivity to water vapour. In addition, it has been established that biopolymers such as gellan gum, xanthan gum, gum arabic and iota-carrageenan are effective for the dispersion of CNTs in aqueous solutions. Well known examples of surfactants and polymers include, sodium dodecyl sulfonate, Triton X-100 and polystyrene sulfonate. To overcome this issue, a diverse range of molecules have been used to aid the dispersion of CNTs in aqueous media, such as surfactants, polymers and biopolymers. However, one of the main disadvantages of CNTs is their process-ability they are difficult to disperse in most common solvents due to their high surface energy and van der Waals interactions. Carbon nanotubes (CNTs) have attracted attention due to their unique electronic, mechanical, optical and thermal properties, which make them suitable for applications in nanotechnology.

0 kommentar(er)

0 kommentar(er)